Friday Factory - An Entrepreneurs Insight

How To Test Your Products

01 September 2023

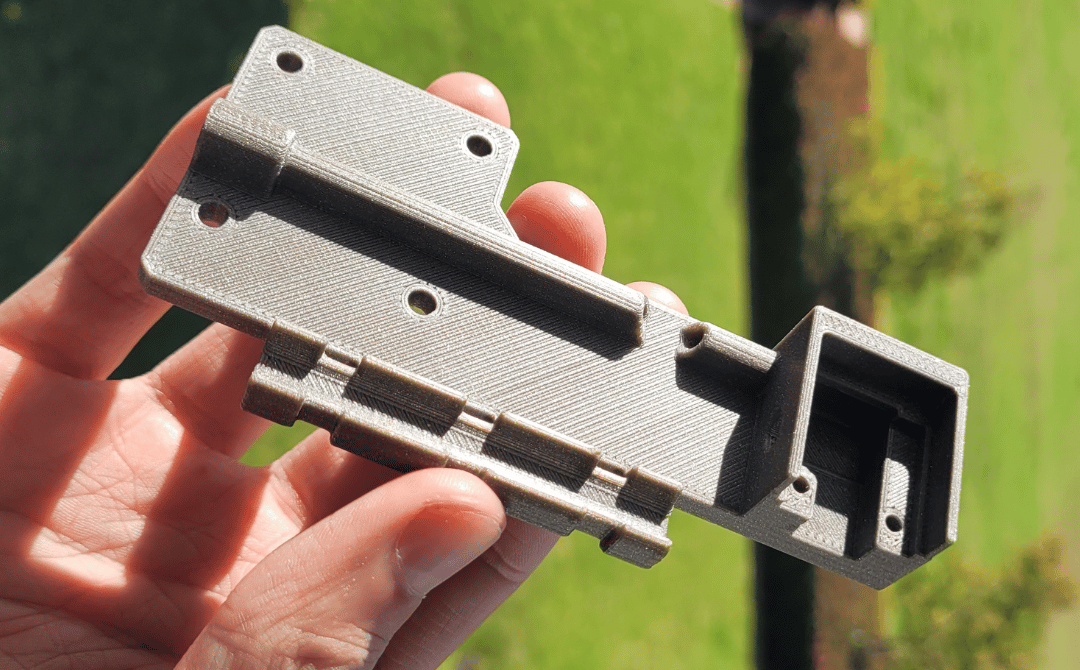

When creating 3D printed items or products that people sell, people nearly always fall into one of two common traps.

The first is inadvertently going down a rabbit hole of “optimising” the product in every way you can conceive.

Now I’ve already spoken before about how this perfectionism will actually hinder your progress,

So today I’m going to be sharing with you the biggest crime.

And that’s a complete disregard to situational product testing.

The amount of time’s I’ve seen products that the designer had every intention of being good - actually come out unfit for purpose for a large portion of their customers that they never expected.

For example, a few weeks ago I found myself in a situation without flipflops. I know, dire straights. So, needing some not-hot footwear pretty quickly, I headed to the local shop to get some replacements.

There wasn’t much choice, but for about 8 Euros I purchased some that seemed OK enough. I couldn’t try them on due to the packaging, but took them home anyway.

Getting them on for the first time, I couldn’t believe it. The tops of my feet (under the straps) were shredded after walking about 30 meters.

I was pretty angry in the moment. Wasn’t expecting Ted Bakers for that price, but just something that wouldn’t make me bleed you’d think would be a reasonable customer satisfaction expectation.

According to the designers, apparently that was too much to ask.

I also found it slightly ironic that printed on them were the words “No hesitation”. Clearly an ethos these guys designed their flip flops by.

Now I’m not sure about you, but I’m fairly used to doctoring brand new products to fit the intended purpose.

Whether it’s replacing a build plate on a printer for something more reliable, converting a dual screen monitor mount into a multi-function station for all my recording gear or hacking a garden incinerator into a meat smoker.

That might be because we’re makers, we like making stuff, and making stuff better. But we forget that most people don’t do this.

For me, I got the flip flops off straight away to figure out why someone would make the straps out of razor blades.

Turns out, the straps were made of that sort of medium density flexi foam.

Now here’s the thing - this foam is bought in sheets by the manufacturer, and cut down to make the straps. The way this foam is cut, is with big hot-knives, that half cut and half melt through it.

This gives a very nice, aesthetically pleasing edge to the top of the straps (hence why I didn’t notice in the shop) but underneath it leaves a very sharp edge that’s harder than the rest of the foam.

Naturally, I got some sand paper and just smoothed this down. A few minutes on each strap and hey presto, we’ve got flip flops that work without the pain.

The equivalent with 3D printing is like the designer didn’t realise how much elephant’s foot the print might get, so didn’t just add a tiny chamfer at the bottom of the print to take the potentially sharp edge away.

And you might have had this on all sorts of things - assembling furniture is a big one where the holes aren’t quite in the right place, so you’ve gotta drill new ones.

And these frustrations are always caused by the same problem - the designer made an assumption that the product would be fine. This is professional complacency.

In the flip flops example, maybe the designers had designed them with a different strap (like fabric etc.) and in the factory they had to swap out the foam for supply reasons or something.

In theory that wouldn’t cause any problems, but if the factory doesn't care about the sharp edges caused by the heat-cut, the designers might not be aware of the impact of the change.

And so the designers may have tested the prototype, but they didn’t test the actual production version. The one with the manufacturing flaws.

The flaw that’s going to cause someone like me 30 meters of walking misery, and a further 2 minutes of angry sanding.

Now it’s your job, as a creator (or designer) of stuff other people will use, to actually test the item in the same capacity your customers intend to use it.

Even if you print your prototypes of product on one type of printer and then start creating on another, you still need to test one of those (for example the elephant's foot I mentioned earlier).

Same goes for when you’re selling enough to either get a print farm, or a traditional manufacturing company to produce them in higher quantities on your behalf.

Because surprises always come up, and it doesn’t matter how good you are at seeing this stuff in advance, there’s probably always something you might not have realised until you’ve sold it.

And for every dissatisfied customer that comes to you with the problem (or leaves a bad review) you can bet they’ll be 10 or so that thought the same but couldn’t be bothered to tell you about it, but probably will tell their friends or others online…

And that’s a surefire way to kill your business before you’ve even got started.

So please, always test your products. Not to perfection, but just in the ways it’s likely to be used by your intended audience.

And if you don’t have something that you need the product testing on (like a specific brand of camper van and you don’t own the van) then just find people that do have them - your customers, and ask their help in testing it.

Ed

Founder of The Institute of 3D Printing

"We Make 3D Printing Simple"

Share this post on:

Ed Tyson

Having successfully scaled multiple ecommerce businesses on a variety of platforms & been featured in online 3D printing publications, he's now looking to help you increase sales of your 3D printed products and identify higher-margin product opportunities to build your wealth.

OTHER POSTS

-

29 August 2023

-

06 August 2023

-

18 July 2023

CATEGORIES

CONNECT WITH ME

Ed Tyson

SUBSCRIBE

Tell us where to notify you when we post:

ABOUT US

The #1 Authority on helping 3D printing businesses scale by finding more profitable, easily 3D printable products, that customers want to buy.

If you’re looking to make more money with 3D printers, let us show you how hundreds of businesses have already transitioned away from feeling overworked and underpaid, to enjoying a solid income and loving their freedom.

© Copyrights by rigid.ink trading as The Institute of 3D Printing. All Rights Reserved.

success@io3dp.com | (+44) 1937 589 052

they can 3D print, then help them scale up sales

they can 3D print, then help them scale up sales  so they can dramatically increase their income.

so they can dramatically increase their income.

and have fun doing it!

and have fun doing it!