Business How-To's

9 Mistakes New 3D Printing Business Owners Make... And What NOT To Sell

18 September 2023

Sometimes, in business, what you don’t do is more important than what you do, do. And in this article I want to bring some attention to a key area that will save you a lot of wasted time and frustration when working out which 3D printed products are in demand.

Your 3D printer (as you know) is capable of making almost anything. Therein lies the problem - we’ve gotta get super focused on what we should do with it.

As with any tool, it’s only gonna be useful if it’s used in the optimal way. We’ve got to factor this in when thinking about ideas for starting a 3D printing business. Because, well… you never get very far hammering in a screw…

Hate reading long, yet hilarious and painfully well written articles like this one?

Here’s the key takeaways and business challenges you can avoid (ignore them at your peril):

-

The non-obvious reason why you should avoid low priced & unprofitable product business ideas that have less than a 10x profit margin

-

Why you should actually avoid really high demand (mass market) products.

-

Avoid selling products that no one wants to buy (and how to spot them before even printing one)*

-

Avoid trending products (well, only in these situations)*

-

Avoid customised products (always, and here’s why)

-

Don’t offer post print finishing (except in this circumstance)*

-

What products that aren’t suited to 3D printing look like

-

Avoid products targeted at low income households to begin with (Tesla effect)

- Avoid products you think people who are already into 3D printing would buy

After that little checklist, you might be screaming “well what should I be printing, then?!” at your screen - don’t worry I’ll get to that (very) soon.

But much like a train needs well defined tracks (restraints) to run freely and go the distance, when we set clear restraints on what we shouldn’t be doing, we give ourselves the freedom to really focus on the stuff that can make our business profitable and successful.

Because honestly, choose the wrong product to sell and your business isn’t going anywhere. In fact, it can be worse than that - you could end up with a product that sells great but doesn’t really make you much money, so you’re working a ton for the same amount as you’d make in a job.

So onto my How To Start a 3D Printing Business Rules…

1) “Thou shall not sell low-profit items”

(Ignore the commandment-esque drama, it seemed appropriate in the coffee shop I wrote them in...)

Can’t tell you the amount of times I’ve sold products in the past that actually sold pretty well, but the margins weren’t great. It’s like trying to drive on the freeway in 1st gear, you’re screaming just trying to keep up.

Selling higher profit-margin products is like changing up gears. So you want to be selling the most profitable 3D printed items for at least 10 times more than they’d cost you to print / make. Can’t stress this enough - it should be the No.1 priority in your 3D printing business plan.

Might take a little longer to find one, but the extra few hours of thinking time will save you potentially years of excess workload. Seriously, it’s that important.

That’s because 3D printing businesses don’t typically tend to scale well unless you make sure you have the profit margin to absorb operating costs, and all the other little expenses you’ll find a long the way.

With a 10 X margin, means you’re still getting to pocket a large proportion of the sale price even after all fees, shipping, and the government has stolen their cut taxes.

The profit margin can be maximised by being smart about printing time and material usage, and getting your pricing right. I cover this in a lot more detail in other guides.

So if you’re wondering what is the most profitable thing to 3D print; then you’re thinking smart. Keep reading and you’ll get see what I recommend here based on what our clients have done when finding their own profitable 3D printed stuff to sell.

2) “Thou shall not sell mass-market 3D printed products”

Wait, so Ed… you want me to only sell stuff most people don’t want to buy?

Uh huh. Here’s why…

When your product / thing is for everyone, it’s for no one. We want to get specific so that the people who are product is for, can recognise straight away.

I know it seems like a counter intuitive business model, but this is such a common mistake.

An extreme example is Marmite, which is basically the worlds more savoury spread (similar Vegemite for the Aussies) - they openly admit that their product people either love it or hate it.

To attract one type of person, you have to repel others.

It’s like if I’m going to eat at a restaurant. Now personally, if I really fancy a curry, I’ll go to a good Indian / curry house. If I fancy a good pizza, I’ll go somewhere that’s all about pizzas. I don’t want to go to a one-stop-shop that does pretty much everything, really averagely.

So unlike my mate last week who had 4 best men for his wedding because he didn’t want to choose and say no to anyone; just make a damn decision and own it.

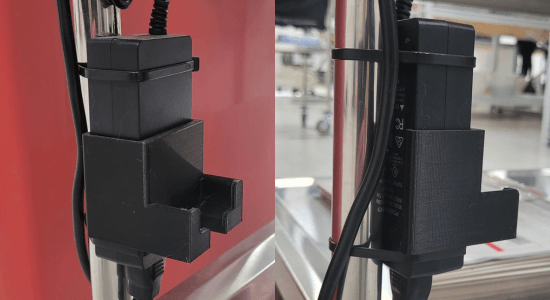

Here’s an example of a highly specialist, niche product - a powerblock organiser and holder for a trolley. Image courtesy of our friends at EvansWerks.

On the topic of owning it, it’s worth noting that with more specialised products you don’t have quite the same pressures of patenting that more mass-market stuff might attract. I’ll cover intellectual property (IP) protection for 3D printed products in another article.

3) “Thou shall not sell products no one cares about…”

OK this is an obvious one, and I don’t need to justify it. But people still do this all the time.

You might think your thing is cool, or your mum does. Your friends might not think it’s terrible - but at the end of the day are people going to pay you enough for this “thing” that will make it worth your time printing and shipping it to them?

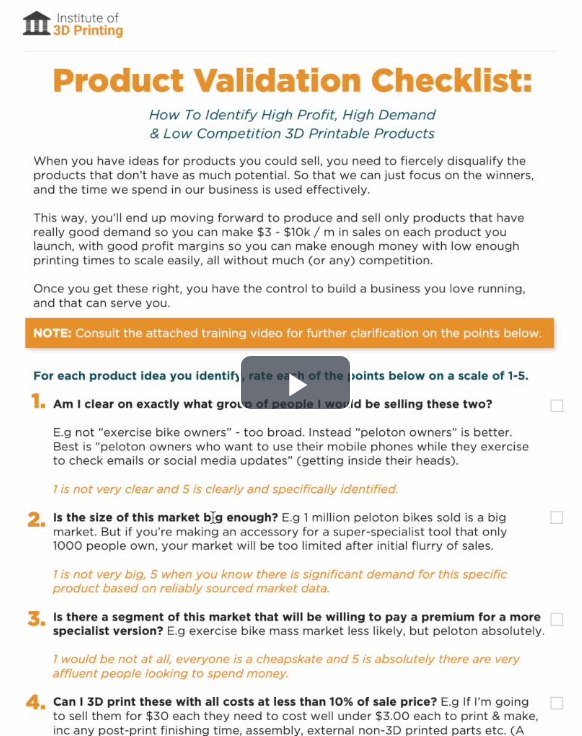

If you want to know how “good” a product is before you even start to create it (a huuuuge time saver) then I recommend grabbing my product validation business checklist, where you can assess a products profitability and viability, before committing time to launching it.

So make sure you prioritise real-world demand as a factor when weighing up different 3D printing business ideas.

If you’re wondering if 'I can just sell 3D printed items from Thingiverse or Printables' you’re likely not going to make sales of significant value, or enough of a profit margin (see #1) or you’ll probably run into IP licensing or copyright issues.

Sorry for the reality check…

And while we’re on reality checks (this isn’t a rant, I promise) often when people ask me the best place to sell their 3D printed items, we talk about Etsy, eBay, Amazon for example.

These are all a good start, because they have these important things, called buyers.

If you’re trying to sell over your own website, while this isn’t impossible - it’s just much harder to get started because:

a) building a website that converts visitors to buyers takes mega time and can be expensive, and…

b) then you have to get cash ready buyers to it.

Trust me, I’ve built 8 ecommerce websites and sold over a million dollars of stuff on them. But I’ve sold multiple millions worth of stuff over marketplaces like Amazon, eBay and Etsy.

So start on platforms, then move to your own website when you’re around $10,000 - $15,000 / month in net profit. If you’re looking to upsell and cross-sell 3D printed products to maximise customer value, only at that stage will having a website be the best way to do it.

So maybe stop selling cutesy little trinkets that aren’t interesting / desirable / useful to anyone.

Especially if everyone else is selling them - they’re likely on borrowed time (if it’s a stupid trending product for example) and you’re probably not going to do that well with them. Leads me onto my next point nicely…

4) “Thou shall not sell trending products”

Hear me out on this - this isn’t a blanket statement in all instances, but you certainly shouldn’t start out on these. Trending products can create a rod for your own back if you don’t know how to use them properly.

Why?

Because when you hit on a trending product, everything is great. You’re making money hand over fist. I remember when I was 18 and sold my first product and it took off. I made over £8,000 (about $10,000) net profit in 3 weeks.

Making money like that is like getting addicted to crack. I’ve never been addicted to crack, but people say it’s amazing.

You think you’re amazing. You’re busy working, but you’re thinking “that was easy, I’m f**king awesome at business”.

But when that trend runs out (and they do) - you’re back to square one. It’s like when Chat GPT first came out and everyone and their dog was sharing AI productivity hacks on TikTok - once we get the inflated euphoria of the trend out of the way we can get down to the real progress.

And all that time you were making sales, it tricked you. You think the good times will last, that the wave will ride forever. You might have a decent bank balance for now, but you didn’t spend any of that time working on your business.

Time spent really working out how to scale your 3D printing business.

So when the sales run out, you still don’t have a business, and you have a pit in your stomach that makes you feel like a bit of a loser. At least, it did for me first time it happened.

Now there are definitely times when it’s a great idea…

You don’t need multiple printers to start a profitable 3D printing business.

I had a client last year have a 6 week straight run of selling a trending product he created after I worked with him, making upwards of $600 / day in net profit. That’s total profit, after all costs (not revenue).

He only had 4 x 3D printers, for the record. This might sound like insane growth, but this isn’t unusual.

But - he was experienced in the business, he had other products that he sold too to pay the bills after the trend died down. It wasn’t his first rodeo, as they say.

I don’t know who “they” are; in England we don’t have rodeos.

So that’s great when it’s not your only product, and you already have a stable foundation of “evergreen” products to pay the bills. Then, you can make hay when it rains.

5) “ Thou shall not customise your products for customers”

Want to work less in your business? And make more money?

Then don’t use 3D printers for something they’re essentially great at (in theory); mass customisation.

I know, I know - we hear it from so many of those who just haven’t done it when we’re searching how to start a 3D printing business, that its great for providing custom stuff.

But this poorly formed advice will prevent you from growing.

That’s because the printers are ideal for putting a custom name or text entry onto a ton of different trinkets and gifts etc. - but at the moment it still takes manual work.

Even if it’s just adding someone’s dogs name to a name tag, might only take you 5 minutes. But that’s still manual labour. And manual labour doesn’t scale.

Systems scale. Automation scales. So we’ve always gotta be thinking “what would this task look like if I had to do 100, or 1000 of these?”.

Do you really have time to be spending 500 minutes per week or month pasting dogs name’s onto STL files, when dogs can’t even read?

Same goes for post print finishing…

6) “Thou shall not “do” post print finishing”

We’re talking sanding, painting, glossing, dipping, filling, whatever.

Just say “NO”.

Design your files better, choose products where it doesn’t matter, or tune up your printer. But don’t offer your time (that should be spent growing the business) adding unnecessary, time-sucky “finishing touches”.

The only exception, is if you’re offering something painted, and you’re either able to do them very quickly and easily in massive batches (i.e something very small and quick to spray paint) or it’s a bespoke effect of paint that also doesn't take long so you charge a lot of money for as an “up-sell”.

I have clients that do both, and because they’ve got the processes setup to do this, and charge enough it’s actually a profitable move for them. But if not, you’re usually just adding messy, unscalable work for not enough return.

7) “Thou shall not sell products that don’t make sense to 3D print”

3D Printing, as we’ve already discussed can be used for like, nearly anything.

BUT - but, 99% of stuff it shouldn’t be used for (in terms of products you could sell).

That’s because 3D printing is brilliant at some stuff - like speed; i.e creating some stuff tomorrow instead of waiting 3 months from a supplier, and complexity is free so you can make stuff stronger or lighter or better looking than injection moulding.

But it’s terrible at competing with anything that’s already injection moulded. They can do it cheaper, make more than you, and have a smooth finish (if that’s required for something that needs it - a lot of stuff doesn’t).

So bare this in mind when you’re wondering what the top selling 3D printed items on Etsy are, because what no one will tell you is that many of these products aren’t profitable at all - even if they look like they’re selling like hot-cakes.

So don’t try. Stick to things that we can make with 3D printers that injection moulding or other stuff can’t compete with. For example, stuff that sells in lower manageable amounts, where you can “fly under the radar” of larger companies looking to injection mould stuff.

8) “Thou shall not sell products to people who can’t afford them”

I might get flack for this, but it makes solid business sense. Trying to sell products specifically to people who don’t have much money is going to be harder to make the sale, and you’re going to make less money per sale.

And… as anyone whose dealt with people and selling products before will tell you; cheaper customers tend to expect more or have more problems. All this adds complexity in a business (and for essentially less reward).

Instead we want to focus on the “Tesla strategy”. Uncle Elon in the beginning stated that he wanted to sell a mass-market electric car that most people could afford.

So why did he start with the $100,000 Model S as his first car? Was he “doing a politician” and not listening to what his mouth was saying?

No, his strategy was to sell a higher profit model, in lower volumes first. This meant he could raise the money he needed to to build a bigger business for later (lower costs, better equipment etc.) and get the skills needed to run a small car company and work out all the teething problems on a smaller scale first.

Elon getting the big bucks first, before offering the cheaper models later.

And then he could create something that was more mass market, much lower profit margin but that sold in much higher numbers (enter; the Model 3).

If he’d have tried to do the low profit, mass market approach “to the masses” kind of product in the beginning, he’d never have been able to work out these advantages and have the room for error (profit) to do so.

It’s a solid strategy that many businesses have successfully utilised to date, including here at the Institute of 3D Printing. We sell our higher priced courses and services first, and then we introduced lower priced products (including a lot of free stuff) so we could help as many people as possible at least at some level.

It’s worth factoring in when you’re deciding on how you can utilise upselling and cross-selling of your 3D printed products to grow the value of each customer. Many customers once they have the confidence in you will want to purchase more.

Don’t forget in business; half the battle is doing the right thing at the right time. So many of us do the right thing, but at the wrong stage - so essentially in the wrong sequence. Unfortunately that’s the same as just doing the wrong thing.

9) “Thou shall not try to sell to your likely competitors…”

There’s a lot of niches out there that tend to overlap heavily with 3D printing enthusiasts. Like cosplay, table top gaming, general computing, etc. etc.

If you’ve been wondering what the top selling 3D printed items on etsy were and scrolled down a “3D printed” search, you’ll see exactly what I mean. 3D printed glitter dragons, or movie prop replicas.

These people are for the most part, not going to buy something that they could 3D print themselves. They’ll probably ask for your STL. Or spend many, many hours redesigning it themselves from scratch just so they don’t need to buy it.

Hey I’m not making fun - it’s just how it is…

Worse, some may only buy it so they can reverse engineer it to sell knock offs of your hard work.

Now competition is eventually inevitable, and when you position your product correctly - you don’t need to worry about it so much. But why throw your lunch to hungry sharks…

So the best people to sell to are those than typically might not have 3D printers (or a desire to build / fix stuff themselves) and while you’re here and possibly wondering; the best place to sell 3D printed items is typically wherever your customers are looking to buy them, which is often eBay, Etsy and Amazon to begin with.

And that’s it - 9 things to definitely never ever do when starting a 3D printing business selling items you’ve made; except in specific circumstances which I’ve outlined above. These factors are critical when working out how to differentiate your 3D printing business.

Now if you’re feeling a bit overwhelmed and no idea where to turn on what you should actually be doing with your 3D printer to make money, don’t worry I’ve got you covered.

If you’re wondering what some of the most profitable 3D printed items could be, I’ve put together a free PDF download of 7 profitable 3D printable product examples you could each sell to make thousands per month. Click the button below to grab your copy.

Share this post on:

Ed Tyson

Having successfully scaled multiple ecommerce businesses on a variety of platforms & been featured in online 3D printing publications, he's now looking to help you increase sales of your 3D printed products and identify higher-margin product opportunities to build your wealth.

OTHER POSTS

-

01 September 2023

-

29 August 2023

-

06 August 2023

CATEGORIES

CONNECT WITH ME

Ed Tyson

SUBSCRIBE

Tell us where to notify you when we post:

ABOUT US

The #1 Authority on helping 3D printing businesses scale by finding more profitable, easily 3D printable products, that customers want to buy.

If you’re looking to make more money with 3D printers, let us show you how hundreds of businesses have already transitioned away from feeling overworked and underpaid, to enjoying a solid income and loving their freedom.

© Copyrights by rigid.ink trading as The Institute of 3D Printing. All Rights Reserved.

success@io3dp.com | (+44) 1937 589 052

they can 3D print, then help them scale up sales

they can 3D print, then help them scale up sales  so they can dramatically increase their income.

so they can dramatically increase their income.

and have fun doing it!

and have fun doing it!